Precision forging is a sophisticated metal forming method for generating nearly net shapes of parts, which are very close to the final shape produced by machining with the highest possible precision and mechanical properties. Compared to conventional forging, it decreases the amount of machining required and improves the use of materials. The automotive, aerospace, oil & gas, and heavy engineering sectors increasingly use precision forged parts to produce high-performance components.

The following are seven important benefits of precision forging, which make it a desirable manufacturing process.

1. Superior Mechanical Strength

The primary advantage of precision forging is the significant increase in strength of the metals used in manufacturing forged products. When metals are processed using forging, the flow of their internal structural materials through the formed component follows the exact dimensions of that component. This process creates an internal structure of forged components with superior tensile strength, better resistance to fatigue, and greater ability to withstand the effects of impact than similar components produced through casting, machining, or any other manufacturing method.

2. Near-Net Shape Production

Precision forgings yield parts with almost finished dimensions. Producing Near-Net Shape reduces the need for additional machining.

Reduced Machining means reduced production time, labor costs, and materials wasted; therefore, improving overall production efficiency.

3. Excellent Dimensional Accuracy

The accuracy of Precision forging is more than conventional or traditional forging process. The advanced dies and precise control provide consistent accuracy across all parts produced in batch quantities.

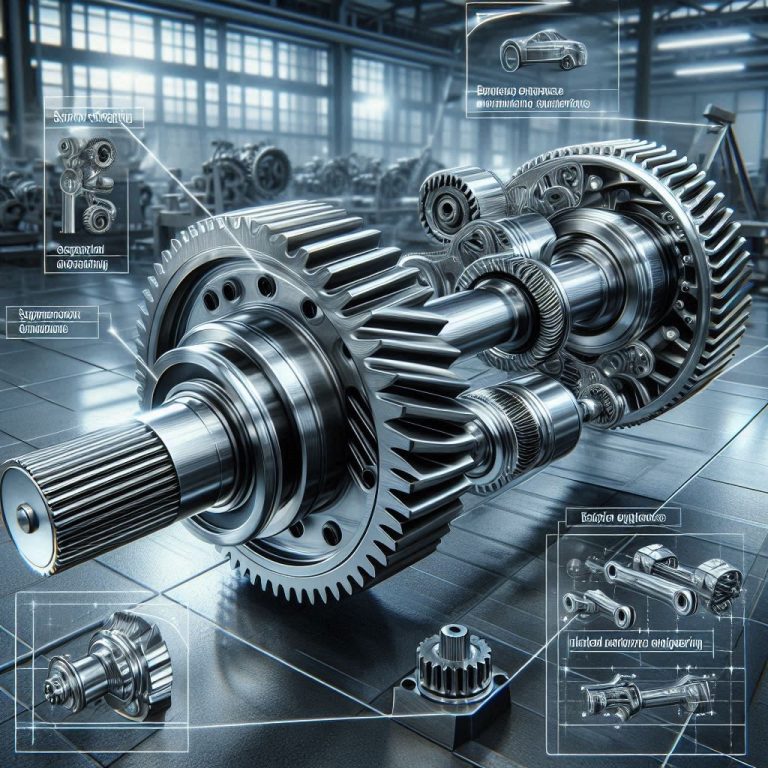

For applications requiring exact fit of components, including automotive gears, shafts, flanges, and structural members, precision forging will provide the needed accuracy.

4. Better Surface Finish

Precision forged parts are typically produced with a significantly improved surface finish than that of conventional forges and therefore require less finishing after being forged (e.g., no need to grind/polish). As such, precision forged components also have lower total costs and have reduced production cycle times when compared to traditional methods.

5. Reduced Material Waste

Another significant advantage of precision forging is increased material efficiency because precision-forged components are made as precisely as possible, there will be very little to no excess material (or scrap) produced from this process.

Improved material utilization lowers the cost of raw materials while contributing to sustainable manufacturing methods.

6. High Production Consistency

Precision forging guarantees uniformity during a lengthy mass production process. When properly designed and made for many components (think thousands!), precision forged die will consistently produce an identical component from start to finish. Therefore consistency has become a must have in problem solving and production within the automotive industry or aerospace industries since both of these industries rely on consistent quality from their product.

7. Cost-Effective for Large-Scale Production

Despite the initial tool investment being greater than other processes, precision activity will have significant cost benefits considering a large volume production run.

Reduced machining costs, reduced waste of material, reduced amount of finishing required, and shorter production time all help to reduce the overall capital cost. All of these factors make precision processes an economical option to many original equipment manufacturers (OEM’s) and other industrial companies.

Conclusion

Precision forging provides a powerful balance of strength, accuracy, efficiency, and cost savings. With superior characteristics in terms of mechanical performance, waste reduction, and production consistency; precision forging is an excellent method for manufacturing high-quality industrial components.

When manufacturers are looking for stronger, lighter, and more durable products they have turned to precision forging as one of the key technologies for achieving modern engineering and manufacturing success.